5 Innovative Technologies Impacting the Engineering Sector

14 Nov, 20239 minutes

The engineering sector has always been at the forefront of technological innovation, constantly pushing the boundaries of what is possible to design, build, and maintain our increasingly complex world. In recent years, the pace of innovation has accelerated exponentially, thanks to breakthroughs in various fields. From cutting-edge robotics to augmented reality solutions, engineers are now armed with various innovative technologies that are transforming how they approach their work.

In this guide, we’ll delve into 5 of the most exciting technologies that are changing the face of the engineering industry.

5 of the Most Innovative Technologies in Engineering

The emergence of groundbreaking technologies has had a transformative effect on the engineering sector. Not only has the implementation of technologies such as robotics and AI changed the way that engineers work, but it has also been effective in streamlining product development and cutting research and development costs. For instance, a study by McKinsey and Company found that digital twins technology can speed up time-to-market time by 50% and boost product quality by 25%.

This is but one example of an engineering innovation that has reshaped the sector, and given the UK government’s pledge to invest £22 billion into research and development funding, it is likely that new and emerging technology will continue to play a vital role for many years to come. So, what are the key innovative technologies that are having the biggest impact on engineering?

Here are 5 cutting-edge technologies that are revolutionising the way that engineering companies operate:

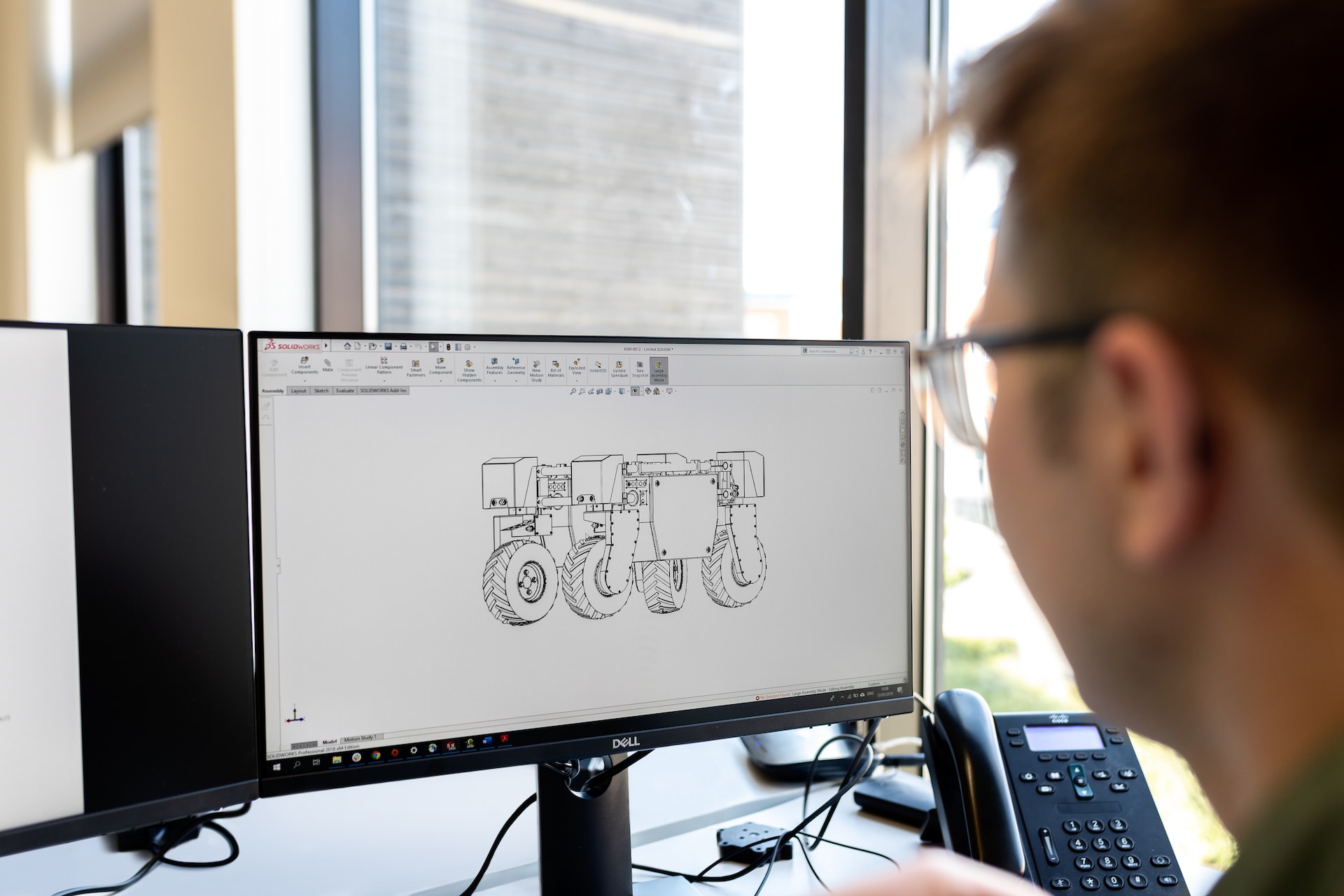

1. Robotics

Robotics is a rapidly evolving field that significantly impacts many areas of the engineering sector, with applications in manufacturing, construction, healthcare, and more. This cutting-edge innovation can completely alter the way tasks are performed, all while boosting efficiency and expanding the possibilities of what engineering can achieve. According to IndustryWeek, it is estimated that robots will eventually take over up to 25% of the work engineers currently do.

This staggering figure demonstrates just how pivotal robotics is to the future of engineering, and considering its various applications, it is not unsurprising. From automating the manufacturing process with robot-controlled production lines to overseeing quality control procedures, the field of robotics already has a wide array of implementations, and as the technology advances, the prospect of robotics becoming completely autonomous in the near future is not beyond the realms of possibility.

Here are the most common uses of robotics in the engineering sector:

Automation of manufacturing tasks like welding, painting, and assembly

Inspecting products to ensure that they meet quality standards

Performing material handling tasks in factories and warehouses, such as transporting heavy loads and optimising logistics operations

Carrying out construction tasks such as bricklaying, demolition, and concrete pouring

Monitoring of environmental conditions using sensors

Although robotics has made it possible for engineering companies to improve productivity and save money, there are various misgivings about the transformative nature of the technology. Many have expressed unease over its potential to remove the need for human labour, a concern that is most certainly valid considering the IndustryWeek statistic we referenced earlier. There are also financial challenges to take into account, including the high startup costs and the need to hire highly skilled staff to programme, operate, and repair the technology.

In spite of the drawbacks, the increased adoption of robotic technology is likely to create a variety of new employment and education opportunities, particularly in technician and maintenance roles. By embracing robotics, your business has a golden opportunity to automate menial tasks, improve product quality, and cut costs.

2. Artificial Intelligence and Machine Learning

Artificial intelligence and machine learning are some of the most innovative technologies of the 21st century, and their rapid development shows no sign of diminishing any time soon. In fact, there is a clear economic imperative for the increased adoption of artificial intelligence, with data showing that the UK’s GDP will be 10.3% higher by 2030 thanks to AI technology. AI and machine learning are bringing about transformative change in many industries, and the engineering sector is no exception.

Like robotics, artificial intelligence offers a number of key advantages for engineering companies. AI and machine learning algorithms are able to streamline and automate laborious tasks, allowing engineers to focus more of their time on other, more essential duties like product design and quality control. As well as automation, artificial intelligence can be instrumental in enhancing design capabilities, optimising for important factors such as sustainability, performance, and cost.

Engineering companies are already leveraging AI and machine learning for a range of applications, including:

Generative product design

Predictive maintenance based on AI algorithms

Identifying product defects in real-time using machine learning algorithms

Demand forecasting for supply chain management

Building AI-driven management systems for optimising energy usage

Despite AI’s numerous benefits and uses, there are several drawbacks engineering companies should consider before deciding to implement AI and machine learning into their workflows. The most pressing concern is job displacement. While AI automation is beneficial for companies, it risks making certain jobs redundant, leading to unemployment for many engineering professionals. Artificial intelligence also raises ethical concerns associated with bias, as AI-based decisions are susceptible to discriminatory outcomes.

Although it is vital to bear these challenges in mind, artificial intelligence, and machine learning offer many undoubted benefits for the engineering sector. While there is a degree of pessimism about AI’s effect on job security, the technology is expected to create 133 million new jobs globally, many of which will be in engineering. While the drawbacks associated with AI and machine learning need to be addressed, engineering companies that embrace this era-defining technology can look forward to improved efficiency, better product quality, and higher accuracy and precision.

As we have seen with robotics and AI, the significance of innovative technologies in the engineering sector cannot be overstated. If you’d like to discover more about how cutting-edge technology has sparked a renaissance of engineering innovation, read our ‘Top 5 Engineering Projects in the UK and Ireland’ guide.

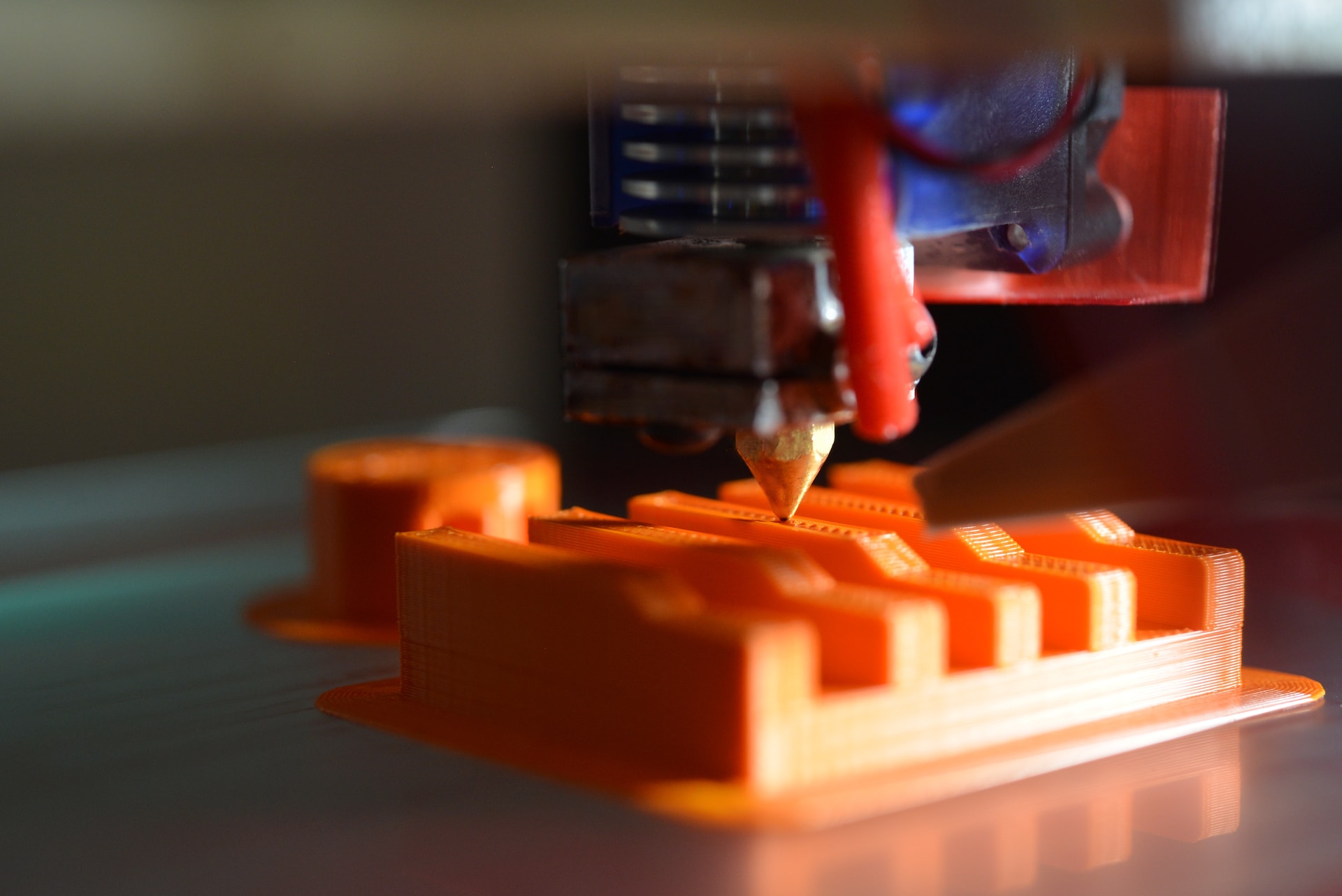

3. 3D Printing

3D printing is another cutting-edge technology that has made a lasting impact on the engineering sector. Defined as making a physical object based on a 3D digital model, 3D printing has become a crucial aspect of product design and manufacturing. Also known as Additive Manufacturing, 3D printing allows engineers to create structures and shapes that would be far too complex via traditional means.

With figures showing that the global 3D printing market is set to grow at a compound annual growth rate of 23.3% between 2023 and 2030, it is clear that this technology will continue to play an active role in the engineering sector for many years to come. 3D printing has already become an essential tool for engineers, enabling them to design new prototypes and address defects without leaving their workstations.

Here are the most common applications of 3D printing in engineering:

Creating prototypes with complex geometries and structures quickly

Designing custom components for the medical, aerospace, and automotive industries

Reducing material waste by adding material layer by layer, as opposed to profligate subtractive manufacturing methods

Replicating legacy parts for older machinery with discontinued components

Facilitating low-volume production runs

Given the sheer amount of advantages that 3D printing offers, it’s no surprise that so many engineering companies are adopting the technology. Its number one benefit is its ability to enable efficient and cost-effective production of prototypes, leading to faster product development cycles. Another aspect that 3D printing excels in is design flexibility, as it allows engineers to create complicated structures that would have been impossible with traditional manufacturing methods.

Although 3D printing is able to streamline the design and manufacturing process without skimping on product quality, there are several downsides to implementing this technology. For starters, 3D printing typically involves high initial investment, largely down to the cost of 3D printers and relevant materials. There is also a limited amount of 3D printing materials compared to traditional manufacturing materials, something that may restrict its usage in certain industries. Other concerns include large energy consumption, copyright infringement issues, and costly post-processing tasks.

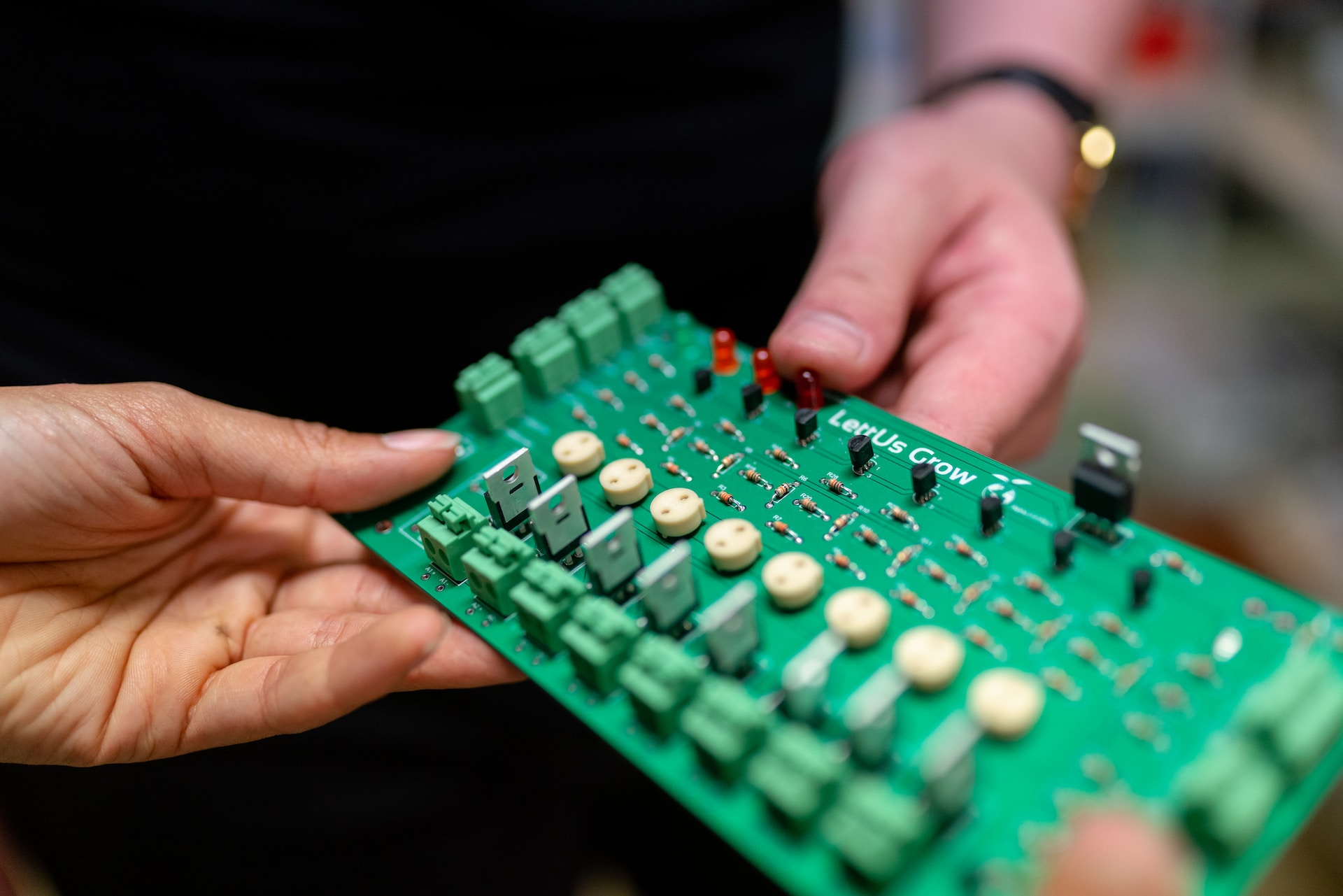

4. Internet of Things (IoT)

The Internet of Things (IoT) is yet another one of the innovative technologies changing the way that the engineering sector operates. Referring to a network of physical objects embedded with sensors for exchanging data with other devices and systems, the Internet of Things has profoundly impacted many aspects of our personal and professional lives. Its ability to optimise manufacturing processes, enable real-time monitoring of systems, and provide data-driven insights make it an ideal tool for engineers.

The adoption of the IoT has grown dramatically in recent years, and the data shows it. It is predicted that the number of IoT devices will rise to 17 billion by 2024, an eye-catching statistic that highlights just how far this technology’s influence will reach. With 90% of companies expected to be leveraging IoT by 2025, it is vital for engineering businesses to get to grips with this innovative technology in order to retain their competitive edge.

Here are the key uses of IoT technology in the engineering sector:

Monitoring the condition of machinery in real time to predict when maintenance is needed

Managing energy consumption by identifying energy-saving opportunities and minimising costs

Tracking the location of goods in transit to optimise the supply chain process

Facilitates smart manufacturing where machines, robots, and systems are interconnected

Automating building management systems like heating control, ventilation, air conditioning, and lighting

IoT technology offers various benefits for engineering companies looking to enhance efficiency, safety, and quality control. IoT devices provide valuable data that engineers can access remotely by enabling real-time monitoring. Its predictive maintenance capabilities are useful for engineers, helping them to identify potential anomalies and failures early and cut down on maintenance costs. IoT sensors can also improve safety by detecting potentially hazardous situations early.

Although implementing IoT sensors and devices provides numerous advantages, it also raises a range of challenges, the most important of which is security concerns. IoT devices are vulnerable to cyberattacks, and weak security protocols can lead to hacking and data breaches. Given that IoT devices deal with vast amounts of data about individuals and organisations, they also spark concerns regarding privacy. Other negative implications of IoT technology include data overload, connectivity issues, and high implementation costs.

5. Augmented Reality

Last on our list of innovative technologies impacting the engineering sector is augmented reality. Until relatively recently, the idea of a technology capable of overlaying computer-generated images onto the real world seemed beyond the realms of possibility. Today, augmented reality is used to aid engineering across a variety of fields, particularly in aerospace and automotive engineering.

Though augmented reality has yet to reach its full potential, it has emerged as a key driving force for innovation in the engineering industry. Research suggests that the technology is capable of addressing ongoing talent shortages, with 78% of engineers claiming that augmented reality is crucial to closing the skills gap in the industry. Additionally, a report published by the Institute of Electrical and Electronics Engineers found that 72% of engineering companies predict that augmented reality will become a key educational tool in the coming years.

These figures demonstrate the transformative effect that augmented reality is likely to have on the engineering industry, but what are its current applications?

Here are augmented reality’s most important uses in engineering:

Visualising 3D models of designs

Enabling remote maintenance and repair assistance via wearable AR devices

Creative immersive simulations for educational purposes

Conducting visual inspections, highlighting defects and anomalies in real-time

Augmenting printed or digital manuals with AR overlays to produce interactive and informative guides

AR technology has benefited a wide array of engineering disciplines, including electrical, mechanical, and industrial. Not only can augmented reality assist engineers in identifying and rectifying design faults before they lead to major problems, but it is also effective in improving spatial intelligence, enhancing professional training, and boosting safety standards. In addition, AR technology contributes to sustainability efforts by reducing the need for physical prototypes.

Though augmented reality is undoubtedly valuable, the technology has several notable disadvantages. AR devices tend to be expensive and bulky, making them difficult for engineers to operate, while AR-powered applications can be susceptible to bugs and glitches. There are also health and safety concerns associated with fatigue and eyestrain that employers must take into account. Like with IoT and AI technology, augmented reality also raises privacy and security issues, not least due to the large amounts of data it processes.

Key Takeaways

The engineering sector is experiencing remarkable transformation, largely driven by groundbreaking technological advancements. Robotics, artificial intelligence, 3D printing, the Internet of Things (IoT), and augmented reality are at the forefront of this revolution, reshaping the way engineers work, innovate, and approach complex challenges.

The future of engineering is exciting, promising to bring about innovative solutions to the challenges of the 2020s and beyond. As we move forward into a tech-driven future, companies should learn to embrace these technologies in order to build a more interconnected world for generations to come while also paying close attention to their ethical and environmental implications.

In a landscape where engineering innovation is accelerating at an unprecedented pace, staying on the cutting edge of technology is a must. The engineering industry's ability to adapt and integrate these innovations will determine its success in delivering solutions that meet the ever-changing demands of our increasingly complex world.

Sourcing Exceptional Talent in Engineering Recruitment

As a leading engineering recruitment agency, we take pride in sourcing exceptional candidates for our clients. Whether you are an up-and-coming firm or a large multinational company, our consultants are ready to provide you with award-winning recruitment solutions. We have been serving businesses and job-seekers alike across Great Britain, Northern Ireland, the Republic of Ireland, and the USA for years, so you can rest assured that we have the means to fulfil your hiring needs.

Reach out to us today to learn more about how we can support you.